As the global chocolate market continues to expand, projected to reach $161.56 billion by 2024 with a compound annual growth rate (CAGR) of 4.2%, the demand for advanced manufacturing technologies such as the Chocolate Coating Machine is more critical than ever. The 138th Canton Fair, scheduled for 2025 in China, promises to showcase innovative solutions that cater to the evolving needs of the confectionery industry. According to a report by Market Research Future, the chocolate coatings segment alone is expected to experience significant growth due to rising consumer preferences for premium and artisanal chocolate products. This event serves as a pivotal platform for industry stakeholders, manufacturers, and technologists to explore the latest advancements in chocolate coating machinery, which enhance production efficiency, product quality, and sustainability in chocolate manufacturing processes. The insights gained at this exhibition will be crucial for businesses aiming to stay competitive in a rapidly changing marketplace.

At the 138th Canton Fair in 2025, the chocolate coating machine sector will showcase groundbreaking advancements that highlight the evolution of chocolate coating technologies. The global chocolate market is projected to reach $161.56 billion by 2025, according to a report by Mordor Intelligence, indicating a robust demand for innovative solutions in manufacturing processes. This increasing demand propels the need for high-efficiency chocolate coating machines that not only enhance production speed but also improve the quality and consistency of coating.

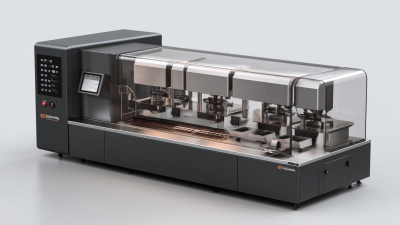

Innovations in chocolate coating technology include the rise of automated systems utilizing AI and IoT capabilities. These smart machines can adjust parameters in real-time to optimize chocolate viscosity and coating thickness, minimizing waste and ensuring uniformity in output. According to the International Cocoa Organization, advancements in coating technology can reduce the production cost by up to 30%, making it an attractive option for manufacturers looking to maximize profits while maintaining high-quality standards.

As exhibitors at the Canton Fair demonstrate these innovations, the chocolate industry is set to embrace a new era of efficiency and quality that aligns with evolving consumer preferences.

The market for chocolate coating machines is anticipated to experience significant growth by 2025, driven by the increasing demand for premium confectionery products and innovative packaging solutions. As consumer preferences evolve towards high-quality and artisanal chocolates, manufacturers are compelled to invest in advanced coating technologies that enhance product appeal and flavor integrity. This trend is particularly evident in the Asia-Pacific region, where rapid urbanization and rising disposable incomes are fostering a booming market for confectionery goods.

Additionally, advancements in automation and smart manufacturing technologies are expected to further propel the chocolate coating machine market. With features such as precision temperature control and enhanced production efficiency, these machines not only improve product consistency but also reduce operational costs. As seen at the 138th Canton Fair, equipment manufacturers are showcasing cutting-edge innovations that cater to both large-scale producers and small artisanal businesses. This creates a dynamic landscape where traditional practices meet modern technology, setting the stage for a vibrant future in the chocolate coating sector.

The upcoming 138th Canton Fair in 2025 promises to shed light on the transformative impact of automation in the chocolate coating machine industry. As manufacturers increasingly focus on efficiency and productivity, advanced technologies are revolutionizing traditional processing techniques. Automated chocolate coating machines are designed to not only enhance throughput but also maintain consistency and quality in the final product. This shift towards automation is crucial in meeting the growing global demand for chocolate products, allowing companies to scale operations without compromising on quality.

Tips for manufacturers looking to implement automation include investing in training for staff to operate new technologies effectively. Ensuring a seamless integration of automated systems can greatly enhance production flows and reduce downtime. Additionally, choosing machines that allow for easy maintenance and upgrades will keep production lines agile and adaptable to changing market needs. Keeping abreast of technological advancements can provide competitive advantages, as companies that embrace automation often see significant improvements in efficiency and cost savings.

Furthermore, linking automation with data analytics can provide insights into machine performance and production efficiency. By monitoring these metrics, manufacturers can identify bottlenecks and optimize processes in real-time. Embracing these technological innovations will not only improve productivity but also position companies at the forefront of the chocolate industry amidst evolving consumer demands.

| Machine Type | Efficiency (%) | Monthly Output (kg) | Automation Level | Energy Consumption (kWh) |

|---|---|---|---|---|

| Batch Coating Machine | 85 | 1500 | Semi-Automated | 200 |

| Continuous Coating Machine | 90 | 3000 | Fully Automated | 180 |

| Enrobing Machine | 88 | 2200 | Automated | 250 |

| Spray Coating Machine | 80 | 1200 | Semi-Automated | 220 |

| Chocolate Moulding Machine | 87 | 1800 | Fully Automated | 230 |

As the 138th Canton Fair approaches in 2025, the chocolate coating industry is placing an increasing emphasis on sustainability practices. Recent reports indicate that the global chocolate market is projected to reach approximately $161.56 billion by 2025, with a significant portion of this growth driven by a rising consumer demand for ethically sourced and environmentally friendly products. In response, manufacturers are beginning to adopt more sustainable practices throughout the chocolate coating production process. This includes sourcing cocoa from certified sustainable farms and utilizing energy-efficient machinery to reduce the carbon footprint.

One of the significant trends highlighted in the latest industry analyses is the rise of biodegradable and compostable packaging solutions for chocolate-coated products. According to a research report by Mordor Intelligence, the global sustainable packaging market is expected to grow at a CAGR of 7.7% from 2020 to 2025, reflecting a robust shift in consumer preference towards eco-friendly options. Additionally, advancements in chocolate coating machinery that minimize waste and energy consumption are vital in meeting sustainability goals. Innovations such as closed-loop systems and real-time monitoring technologies are revolutionizing production efficiency while adhering to environmentally conscious practices. As attendees at the Canton Fair explore the future of chocolate coating machines, the emphasis on sustainability will undoubtedly shape the industry's trajectory in the coming years.

At the 138th Canton Fair in 2025, the spotlight will be on leading manufacturers of chocolate coating machines, showcasing innovations that cater to the evolving needs of the chocolate industry. With the global cocoa market facing significant challenges, as reported by SBM Intelligence, manufacturers are being pushed to enhance production efficiency and maintain the quality of their chocolate coatings. The surge in cocoa prices, driven by tightening supplies, necessitates that producers leverage advanced machinery to optimize their processes and reduce wastage, ensuring the final product remains affordable for consumers.

Major players in the chocolate coating machine sector are expected to present their latest developments, focusing on improving the consistency and durability of chocolate coatings. Technology that minimizes the temperature fluctuations and enhances the coating thickness will be critical for the manufacturers in navigating the surging costs of cocoa. In light of current market trends, it will be important for these manufacturers to adapt and contribute solutions that not only meet consumer demands for quality but also address the economic challenges posed by fluctuating cocoa prices. As the fair unfolds, insights into these technologies will likely shape the future landscape of chocolate production.