In recent years, the confectionery industry has witnessed a remarkable transformation, driven by technological advancements and innovative processes. Among the essential tools revolutionizing this sector is the Enrober Machine, which plays a critical role in the coating and finishing of various confectionery products. As manufacturers strive for higher efficiency, improved product quality, and enhanced consumer experiences, the next generation of Enrober Machines promises to deliver significant benefits, adapting to the ever-evolving demands of the market.

The integration of cutting-edge features and smart technology into Enrober Machines is set to change how confectioneries are processed. With enhanced precision, speed, and automation, these machines are not only increasing production capabilities but also ensuring that quality remains at the forefront. As we delve into the advancements and innovations shaping the future of confectionery processing, it becomes evident that the Enrober Machine is poised to lead this charge, ensuring that manufacturers can meet consumer expectations while driving the industry towards a more sustainable and efficient future.

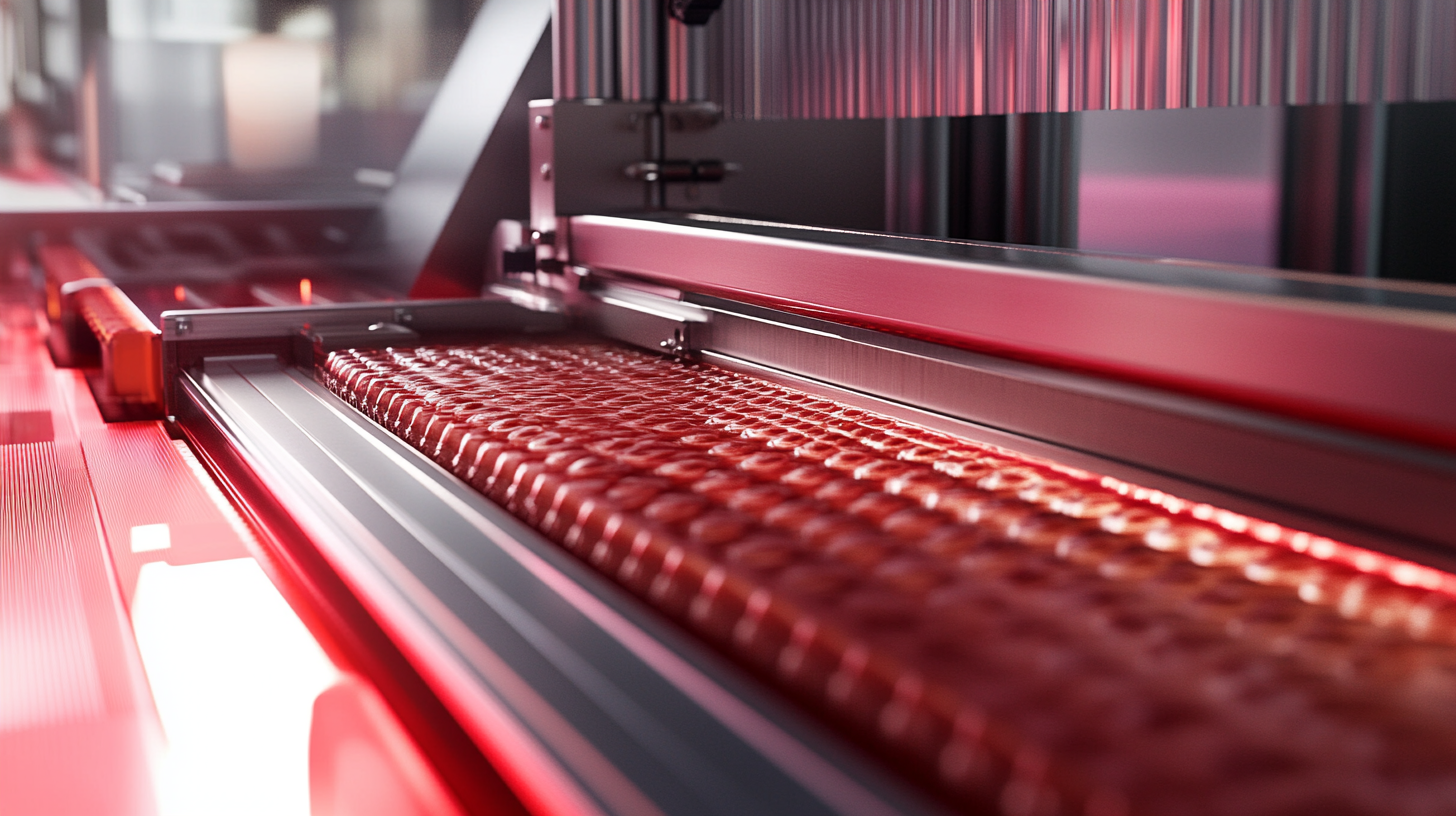

The confectionery processing industry is witnessing a remarkable transformation driven by advancements in enrober technology. The latest innovations are designed to enhance efficiency, precision, and flexibility in coating applications, catering to the evolving demands of manufacturers. According to industry reports, the global chocolate market is projected to reach $161.56 billion by 2025, highlighting the necessity for state-of-the-art machinery that can keep up with growing production rates and refined quality standards. At recent exhibitions, cutting-edge enrober machines exemplify this progress. For instance, at a notable trade show, a chocolate coating machine featuring a 420 mm belt width was showcased, emphasizing the trend towards compact yet powerful equipment. This particular model not only allows for even coating but also optimizes ingredient usage, thereby reducing waste—a critical consideration in the face of rising raw material costs. Moreover, these modern enrobers incorporate advanced automation and smart technology, enabling real-time monitoring and adjustments during the production process. This level of control ensures consistency and quality while minimizing labor costs. As manufacturers increasingly seek to streamline their production processes, these advancements in enrober technology will play a pivotal role in shaping the future of confectionery processing. With a blend of innovation and efficiency, the next generation of enrobing solutions stands ready to support the industry's ambitious growth trajectory.

The confectionery industry is experiencing a transformative shift with the advent of smart enrober machines designed to enhance production efficiency. As demand for high-quality confections rises, manufacturers are increasingly turning to advanced technologies that optimize the enrobing process, a critical phase in chocolate and candy production. Research from industry experts at MarketsandMarkets predicts that the global chocolate market will grow from $128.9 billion in 2021 to $161.3 billion by 2026, underscoring the urgent need for innovative solutions that can keep pace with this growth.

Smart enrober designs are at the forefront of this revolution, utilizing Internet of Things (IoT) connectivity and advanced data analytics to streamline operations. According to a report by Grand View Research, automated machinery can improve production efficiency by up to 30% while significantly reducing waste. These machines monitor temperature, coating thickness, and production speed in real-time, allowing manufacturers to fine-tune parameters for optimal results. This approach not only increases throughput but also enhances product consistency and quality, meeting the rising consumer expectations for premium chocolates.

Moreover, the integration of machine learning algorithms enables enrober machines to learn from previous batches, predicting and adjusting for potential issues before they arise. A study by Allied Market Research highlights that companies adopting smart manufacturing solutions can achieve up to a 20% reduction in operational costs. As the confectionery industry embraces these technological advancements, businesses that invest in high-performance enrobing solutions will be better positioned to compete in a rapidly evolving marketplace.

The confectionery industry is experiencing a groundbreaking shift towards sustainability, particularly with the innovation of eco-friendly enrober machines. These advancements are redefining how chocolate and other confections are coated, moving away from traditional methods that often involve significant energy consumption and waste. By integrating energy-efficient technologies and sustainable materials, modern enrobers are minimizing their environmental footprint while ensuring high-quality product output.

One of the key features of these eco-friendly enrober solutions is their use of renewable energy sources. Many manufacturers are now utilizing solar power and other renewable options to operate their machinery, drastically reducing reliance on fossil fuels. Furthermore, advancements in temperature control and process optimization have led to lower energy costs and a decrease in thermal waste, ensuring that every ounce of energy is efficiently used during production.

Additionally, sustainability in enrobing extends beyond energy usage to encompass the sourcing of materials. Many companies are committing to using biodegradable and recyclable materials for packaging and machine components. This thoughtful approach not only helps confectionery producers align with corporate social responsibility goals but also meets the growing consumer demand for environmentally friendly products. As the industry continues to evolve, eco-friendly enrober solutions will play a crucial role in transforming confectionery processing, making it more sustainable for future generations.

The confectionery industry is experiencing a transformative era with the advent of next-generation enrober machines. As manufacturers strive for efficiency and product quality, the features of these machines have evolved significantly. One key aspect to consider is the precise temperature control systems incorporated into modern enrobers. Enhanced thermal regulation ensures uniform coating, reducing the risk of product defects and maintaining the integrity of delicate confections.

Another critical feature is the integration of advanced automation and user-friendly interfaces. Next-generation enrober machines often come equipped with sophisticated software that allows operators to monitor and adjust processes in real-time. This capability not only streamlines production but also minimizes human error, allowing for consistent product quality. Furthermore, the flexibility of these machines allows them to accommodate various product sizes and coatings, making them ideal for diverse product lines.

Finally, energy efficiency is becoming increasingly important in the design of enrober machines. Manufacturers are focusing on reducing energy consumption while maximizing output, which not only lowers operational costs but also addresses sustainability concerns. By investing in machines that offer energy-saving features, businesses can align their production practices with eco-friendly initiatives while maintaining high standards of quality and efficiency.

Modern enrober systems are at the forefront of revolutionizing the way confectionery products are processed, significantly impacting both flavor and texture. As consumers become more discerning, the demand for enhanced sensory experiences in food has reached new heights. This movement is paralleled in the growing market for plant-based alternatives, where texture and flavor play crucial roles in consumer acceptance. The advanced capabilities of contemporary enrober machines allow manufacturers to create coatings that not only improve the aesthetic appeal of confections but also contribute to a more satisfying taste experience, much like the efforts involved in developing plant-based substitutes that mimic traditional animal products.

The technology behind next-generation enrober machines offers precise control over temperature, flow rates, and coating thickness, translating into better texture profiles for a variety of confections. The focus on maximizing flavor through optimized coating processes aligns with findings from recent research in the bakery and plant-based sectors, where texture greatly influences consumer enjoyment. As confectionery brands adapt to these technological advancements, they're not only enhancing their product lines but also addressing the evolving preferences of health-conscious and flavor-seeking consumers. This synergy between innovative processing techniques and sensory enhancements reflects a significant trend that is shaping the future of the food industry.