In recent years, the global chocolate market has experienced significant growth, with a valuation of over $130 billion in 2021 and projections to reach approximately $200 billion by 2028, according to industry reports. This surge in demand emphasizes the necessity for manufacturers to reassess their production strategies and invest in cutting-edge technology. One pivotal aspect of enhancing operational efficiency within the chocolate industry is the implementation of advanced Chocolate Making Machines. These machines not only streamline the production process but also ensure consistency in quality, which is paramount in meeting the evolving tastes of consumers.

The rise of artisanal and premium chocolate products further underscores the importance of optimizing production lines. A report by Research and Markets indicates that the premium chocolate segment is expected to grow at a CAGR of around 7.5% over the next five years. This trend requires manufacturers to adapt quickly, making it essential to equip production lines with the latest Chocolate Making Machines that can handle increased production capacity while maintaining high standards. By embracing these technologies, chocolate producers can enhance their competitiveness in a rapidly evolving market and meet the growing consumer demands for diversity and quality.

In the chocolate production industry, the integration of advanced machines plays a critical role in enhancing both efficiency and product quality. According to a report by Grand View Research, the global chocolate market is projected to reach $202 billion by 2024, emphasizing the increasing demand for high-quality chocolate. Advanced chocolate-making machines, such as conching machines and tempering machines, ensure that the chocolate's texture and flavor are optimized, which is crucial in meeting consumer expectations. The use of these machines not only streamlines production processes but also minimizes human error. For instance, automated tempering machines maintain precise temperature controls, which can reduce the risk of seizing or blooming in chocolate. A study by the International Journal of Food Science and Technology highlighted that employing automated equipment can lead to a 30% increase in production capacity, enabling manufacturers to scale operations without compromising on quality. Furthermore, the incorporation of cutting-edge technology such as IoT and AI into chocolate production systems allows for real-time data tracking and analysis, leading to better decision-making. According to a report from Mordor Intelligence, the adoption of smart manufacturing solutions in food production, including chocolate, is estimated to grow at a compound annual growth rate (CAGR) of 14.5% from 2021 to 2026. This trend signifies how advanced machines are transforming the chocolate production landscape, making it not only more efficient but also more responsive to market demands.

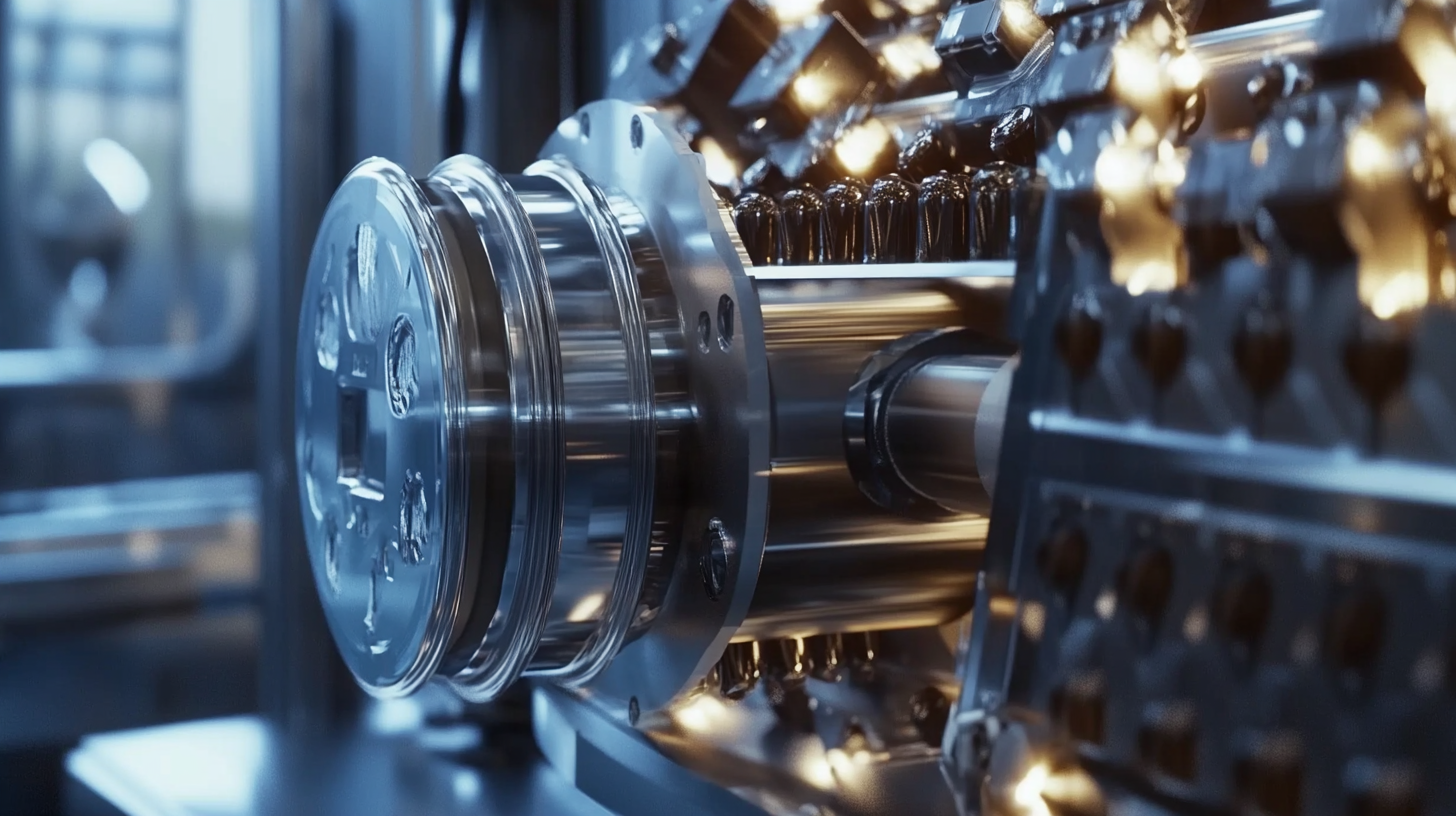

In the realm of chocolate production, modern equipment has redefined efficiency and quality. When considering advanced chocolate making machines, there are several key features that stand out. Firstly, the ability to customize production settings is crucial. Modern machines often come equipped with programmable controls that allow manufacturers to adjust temperature, mixing speeds, and molding processes with precision. This ensures that the unique flavor profiles and textures demanded by consumers are consistently achieved.

Another vital feature to look for is the incorporation of automation technology. Automated systems enhance production speeds and reduce labor costs, which is particularly important in meeting the high demand for chocolate products. Additionally, the integration of monitoring systems provides real-time data on production quality, enabling operators to make immediate adjustments as necessary. This level of oversight fosters a more efficient production line, leading to fewer errors and higher output.

Moreover, energy efficiency is becoming increasingly essential in modern chocolate making machines. As companies face rising energy costs and the need for sustainable practices, selecting equipment designed to minimize energy consumption can significantly impact overall operational expenses. Features like energy-saving motors and heat recovery systems not only bolster production efficiency but also align with the growing consumer preference for environmentally friendly practices.

In conclusion, the advancements in chocolate making equipment not only optimize production lines but also ensure that manufacturers can meet the evolving demands of the market effectively. Investing in machines with these critical features can set companies on a path toward greater success in an increasingly competitive industry.

Streamlining processes in the chocolate manufacturing industry is essential for enhancing efficiency and maximizing output. According to a report by the International Confectionery Association, the global chocolate market is projected to reach $161.56 billion by 2024, emphasizing the need for manufacturers to adopt advanced technologies that enable smoother operations. Implementing modern chocolate making machines not only helps to minimize downtime but also improves the consistency and quality of the products.

Advanced chocolate making machines integrate automation and smart technology, significantly reducing human error in the production line. As per a study by MarketsandMarkets, automation in food production can increase operational efficiency by 25% to 50%. These machines allow for precise control over temperature, mixing, and molding processes, ensuring that every batch meets stringent quality standards. Companies that have adopted such innovations report decreased production costs and shorter lead times, giving them a competitive advantage in the growing chocolate market.

Additionally, optimizing the production line with state-of-the-art equipment facilitates better inventory management and reduces waste. The Food and Agriculture Organization (FAO) highlights that up to 30% of food products are wasted due to inefficient processes. By incorporating advanced chocolate making technologies, manufacturers can streamline their workflow, efficiently utilizing raw materials while maintaining high throughput. This not only contributes to sustainability efforts but also enhances overall profitability, allowing businesses to respond rapidly to consumer demands in an ever-evolving market.

Maintaining quality control is paramount in chocolate production, where consistency and taste are non-negotiable. High-tech chocolate machinery plays a crucial role in achieving this by automating processes that were traditionally labor-intensive and prone to human error. Advanced chocolate making machines are equipped with sensors and monitoring systems that ensure precise ingredient measurements and tempering temperatures, helping manufacturers produce chocolate that meets high industry standards.

Moreover, modern machinery offers real-time data analytics, allowing producers to monitor production metrics continuously. This capability helps identify any deviations from quality benchmarks immediately, enabling swift corrective actions. For instance, if a batch of chocolate is not meeting viscosity requirements, the system can alert operators to adjust the parameters before the product goes further down the production line, thereby minimizing waste and maintaining consistency.

Another significant benefit of high-tech chocolate machinery is its ability to replicate successful production runs reliably. By incorporating automation and standardized recipes, manufacturers can achieve uniformity in flavor, texture, and appearance. This consistency not only enhances customer satisfaction but also helps in establishing a strong brand identity. Ultimately, leveraging advanced chocolate making machines ensures that quality control is integrated into every step of the production process, producing chocolate that delights consumers while boosting operational efficiency.

In the competitive world of chocolate manufacturing, integrating automation into production lines has become paramount for enhancing productivity and reducing costs. Advanced chocolate making machines equipped with automation technology streamline various processes, from mixing and conching to tempering and molding. By minimizing manual intervention, companies can not only speed up production but also reduce the likelihood of human error, ensuring consistent quality in every batch.

Automation also allows for better management of resources. With precise control over ingredient measurements and timing, manufacturers can optimize ingredient usage, reducing waste and lowering material costs. Additionally, real-time monitoring systems enable companies to analyze production data, facilitating timely adjustments that enhance efficiency and output. Implementing such technologies not only leads to immediate operational improvements but also positions manufacturers to be more agile in responding to market demands.

Moreover, the integration of automation into chocolate production lines facilitates a more sustainable manufacturing process. By utilizing smart machines that operate with energy efficiency in mind, companies can significantly cut down on energy consumption, contributing to lower operational costs and a reduced carbon footprint. In today's eco-conscious market, this aspect of automation is increasingly appealing to both consumers and companies striving for sustainability.