Features

- Smooth start-up of the agitator due to the use of a frequency converter - This reduces the load on the mechanical components and ensures a long service life.

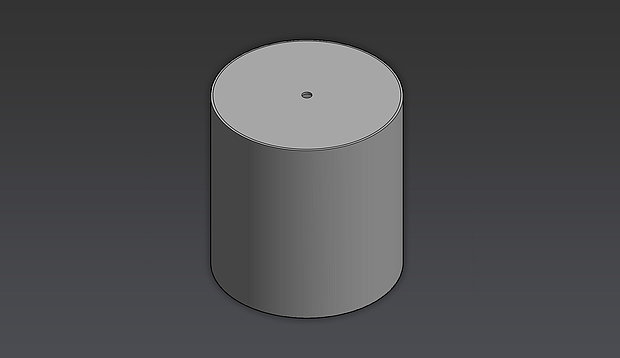

- Integrated, heated work tank approx. 55 cm wide and 38 cm deep

- The capacity of the tank is max. approx. 25 kg min. 8 kg

- Automatic individual shutdown of the heating circuits depending on the filling quantity

- Solid chocolate is dissolved over a period of about 5 hours

- Liquid chocolate can be continuously refilled in small uniform quantities

- Pouring tube is height-adjustable, swivels and can be removed for cleaning

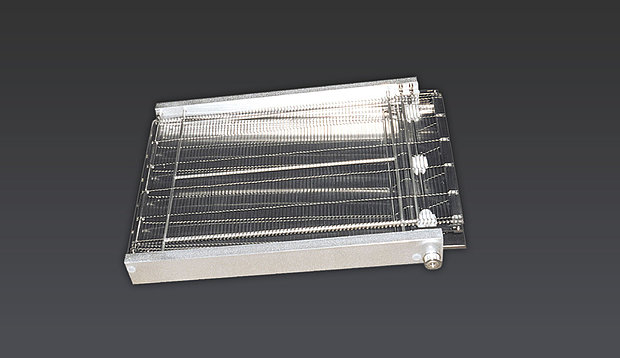

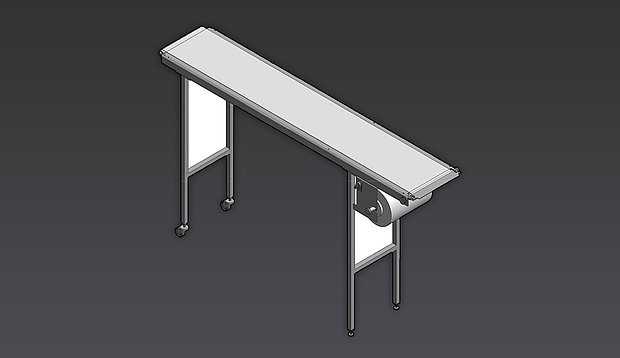

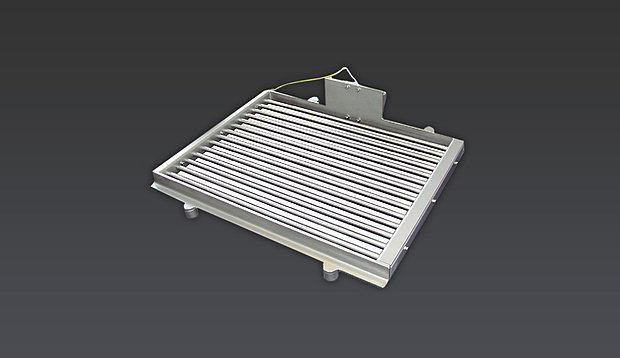

- Covering grid band - easily removable and therefore very easy to clean, also dishwasher safe

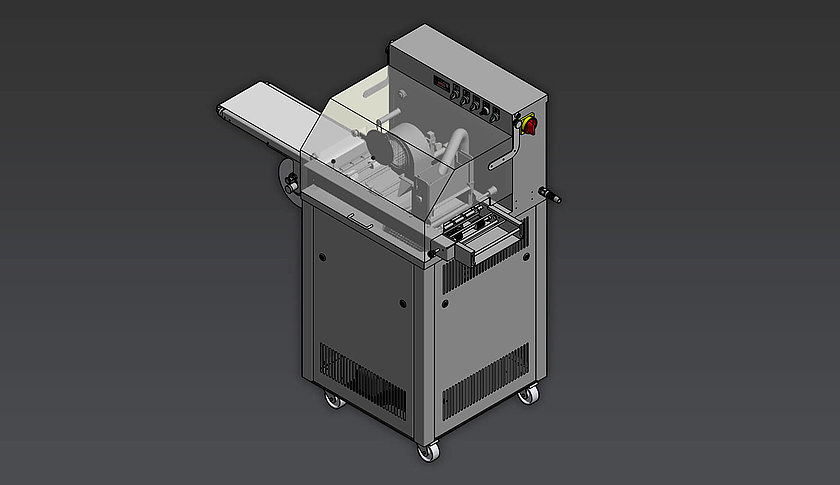

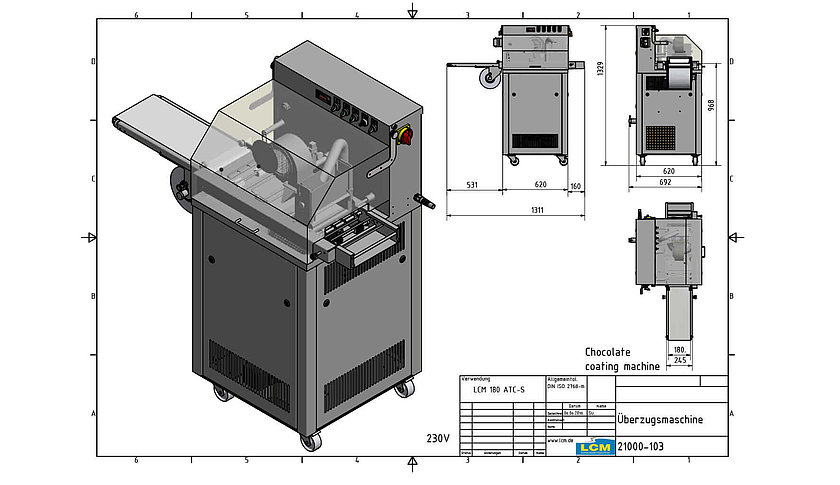

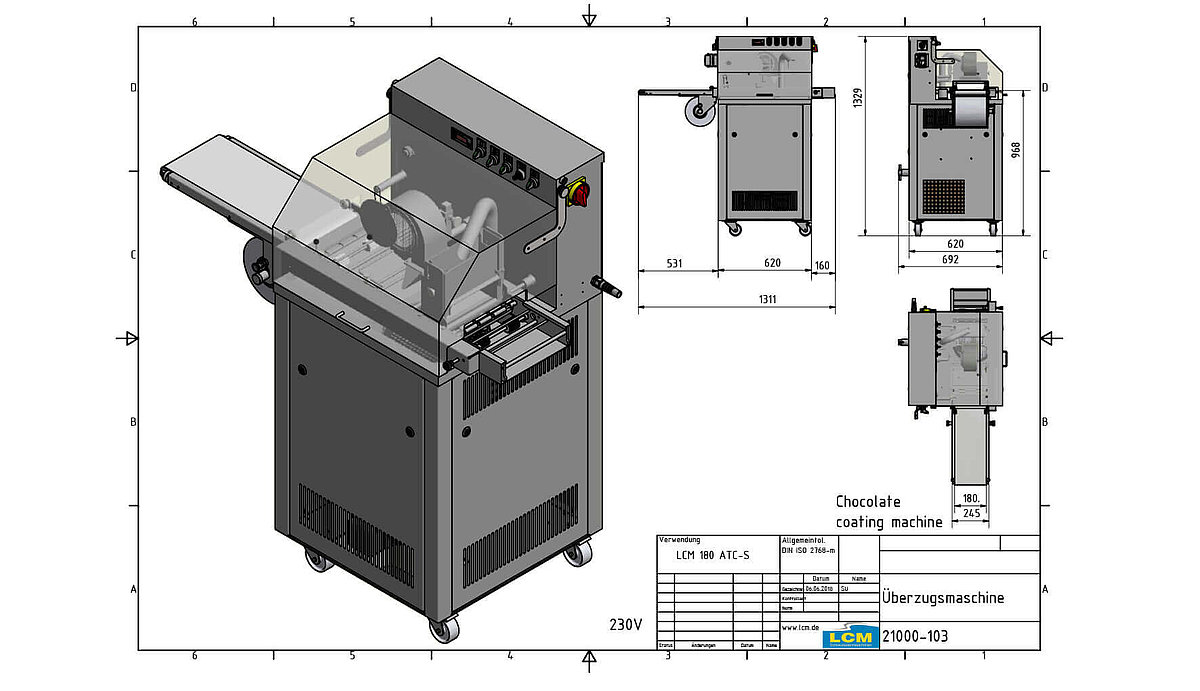

- Total length depending on equipment approx. 1.0 meter

- Infeed grid belt separate from the overlay belt, feeding area 20/40 cm, very narrow transfer even for smallest products

- Covering unit in different variants available as accessories

- Veil box continuously adjustable in height up to 8 cm

- Continuously adjustable blower for blowing off the chocolate after coating

- Blower motor removable and adjustable in height up to 8 cm Plastic hood with hinge for opening

- FI residual current circuit breaker according to DIN VDE 0100-100 - safety of persons

- Machine housing completely made of stainless steel, mobile on swivel castors