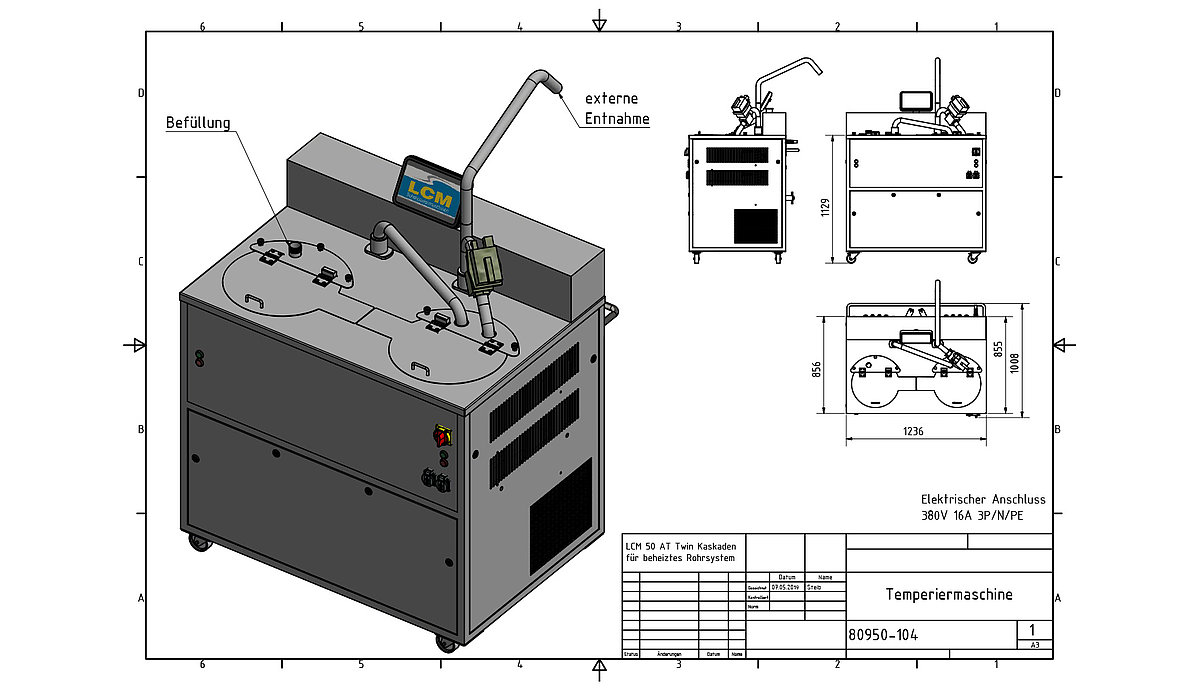

Features

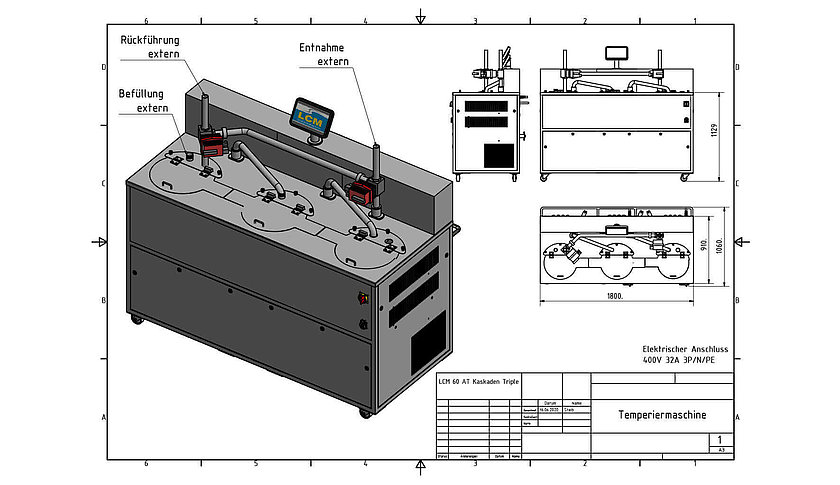

- Continuous temperature control capacity in cascade operation approx. 250kg/hr.

- Continuous tempering capacity in single operation (approx.50-80kg/hour per tank)

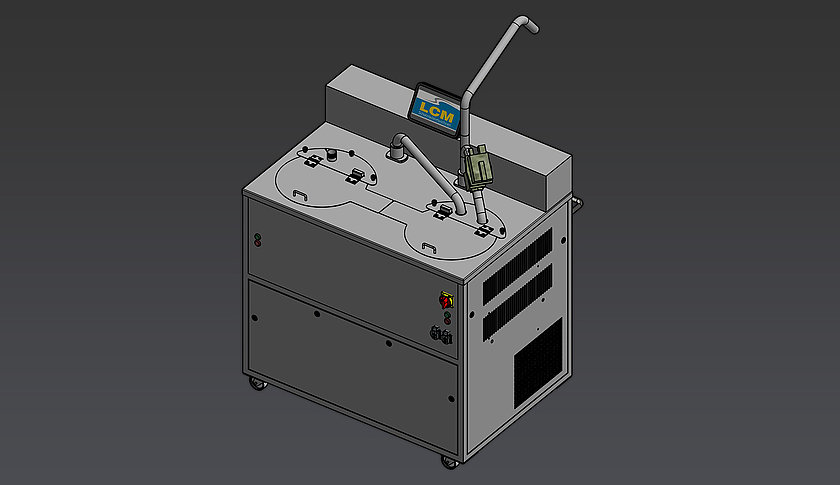

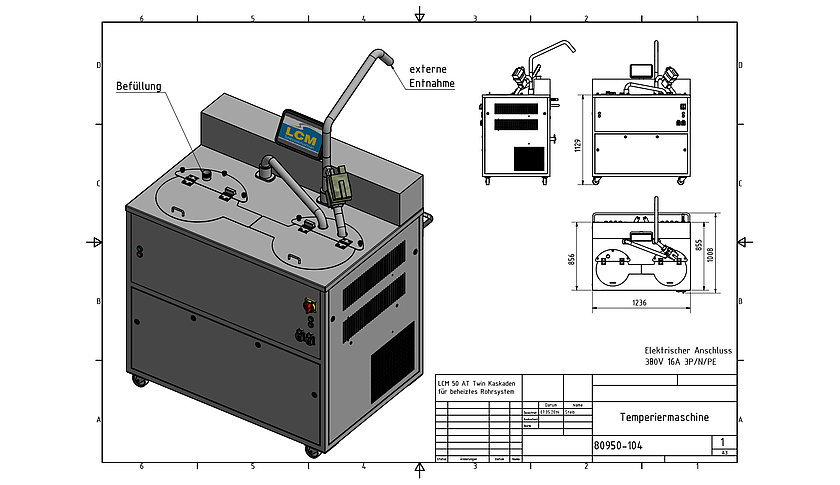

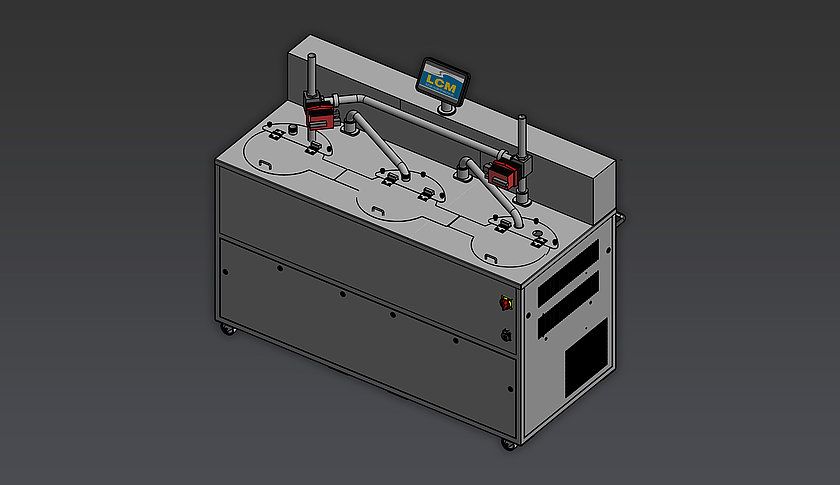

- Two tanks with a capacity of approx. 50 kg each

- Independently operating machines combined in one housing

- PLC control, with 10" glass screen for comfortable operation and easy menu navigation

- Different chocolate temperatures and settings (recipes) are programmable

- Various accessories ready to be plugged in and operated via the touch panel, e.g. heated protective grid or heated pipe system

- Standby function - temperature increase in the tank and interval for the agitator to ensure perfect decrystallization during the work break

- Smooth start-up of the agitator by using a frequency converter, thus low stress on the mechanical components and a long service life

- Automatic, individual shutdown of the heating circuits depending on the filling quantity

- Level measurement "minimum - maximum" via indicator light, ready to plug in, prepared for automatic charging by external dissolver with pump

- FI residual current circuit breaker according to DIN VDE 0100-100 - safety of persons

- Cooling system for temperature control in the lower part of the machine

- Machine housing completely made of stainless steel, mobile on swivel castors