Features

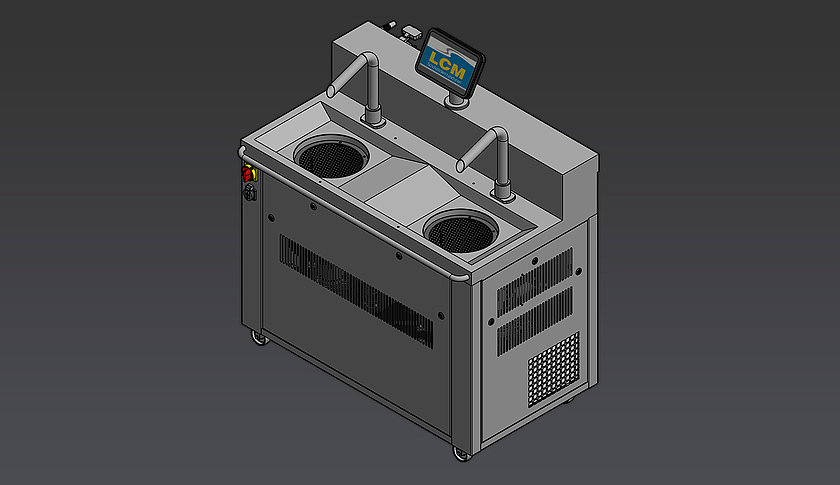

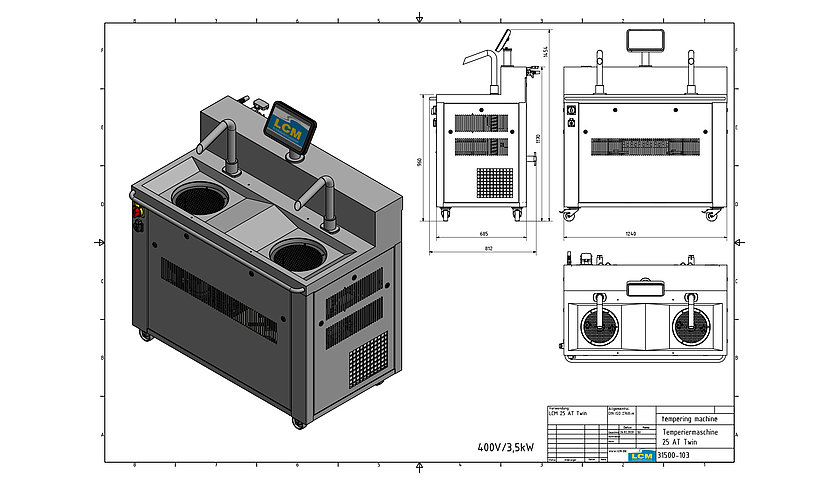

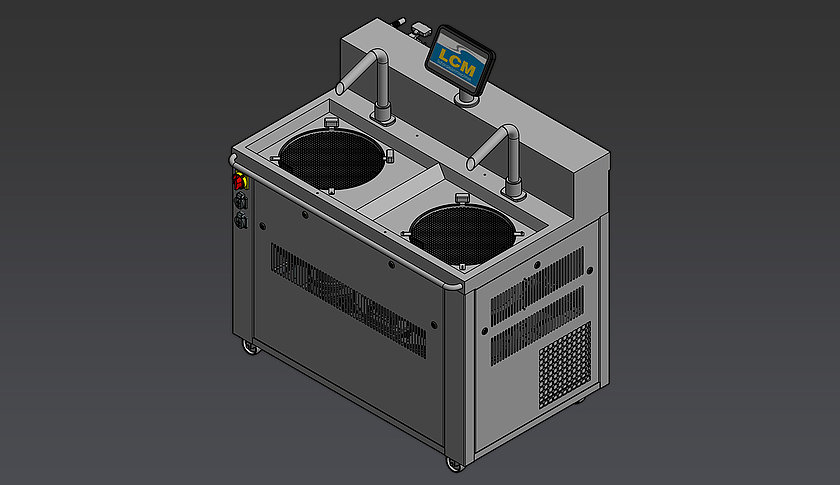

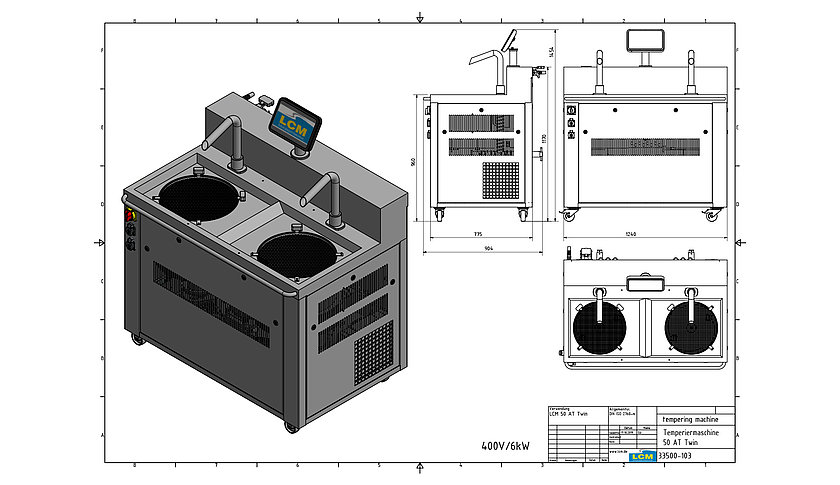

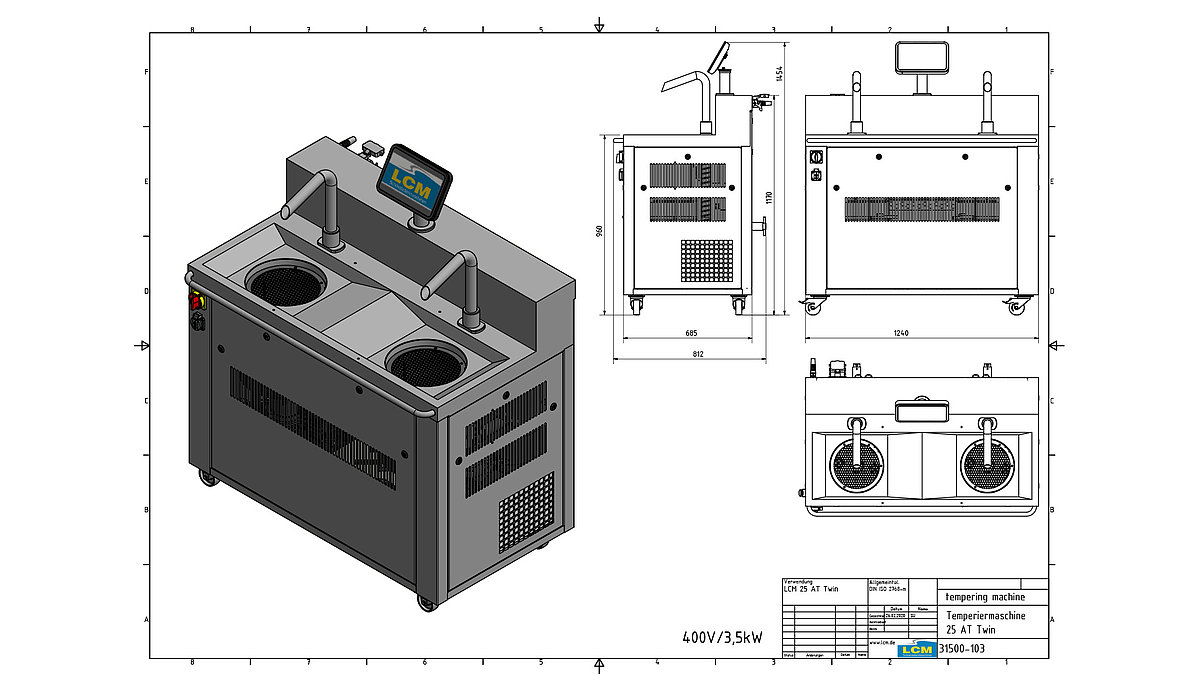

- Two independently operating machines combined in one housing

- PLC control, with 10" glass screen for comfortable operation and easy menu navigation

- Different chocolate temperatures and settings (recipes) are programmable

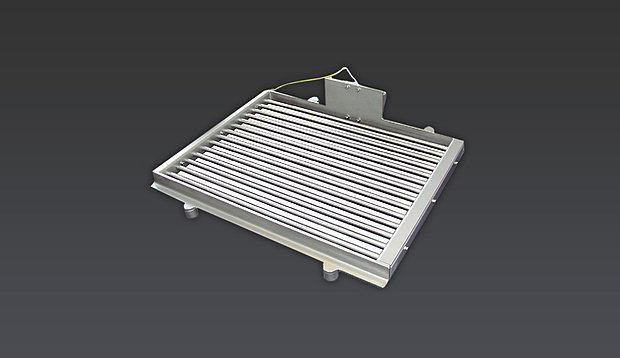

- Various accessories prepared ready to plug in and operable via the touch panel, such as dosing, vibrating table and heated protective grid. A heated pipe system can be retrofitted

- Standby function - temperature increase in the tank and interval for the agitator to ensure perfect decrystallization during the work pause

- Smooth start-up of the agitator by using a frequency converter, thus low stress on the mechanical components and a long service life

- Automatic, individual shutdown of the heating circuits depending on the filling quantity

- Solid chocolate is dissolved over a period of about 8 hours

- Liquid chocolate can be continuously refilled in small uniform quantities

- Level measurement "minimum - maximum" via indicator light, ready to plug in prepared for automatic charging by external dissolver with pump ( with 25 AT TWIN only as optical signal)

- Pouring tubes height adjustable, swivelling and also removable for cleaning

- FI residual current circuit breaker according to DIN VDE 0100-100 - safety of persons

- Cooling system for temperature control in the lower part of the machine

- Machine housing completely made of stainless steel, mobile on swivel castors