Features

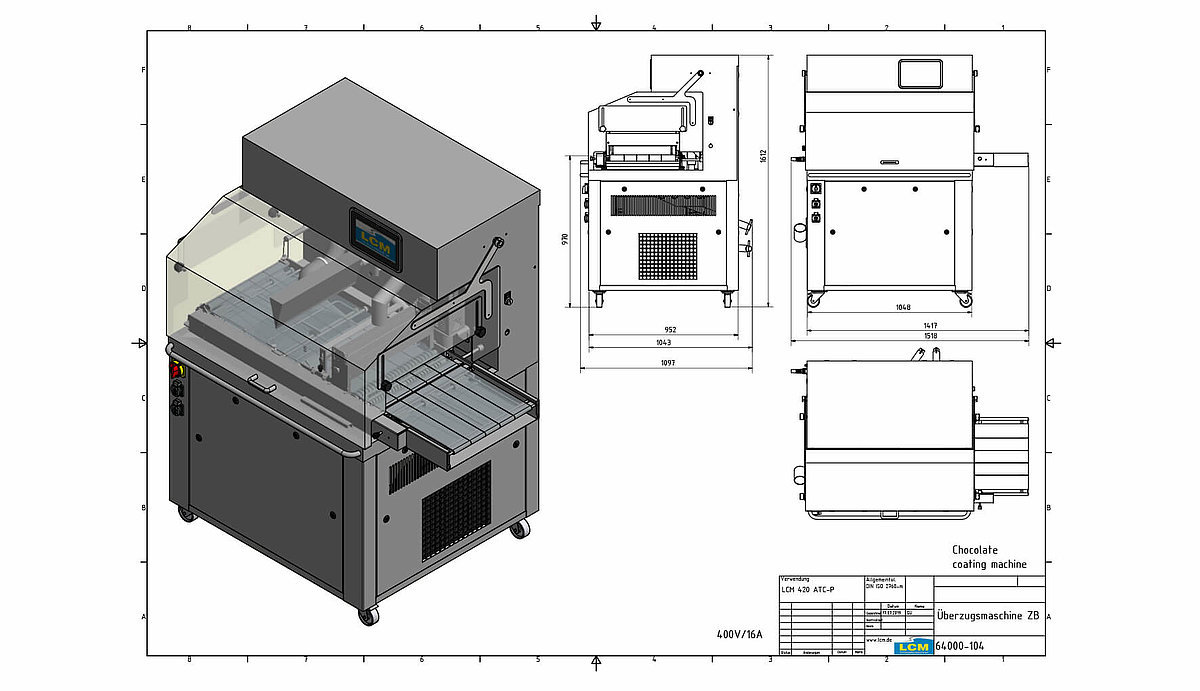

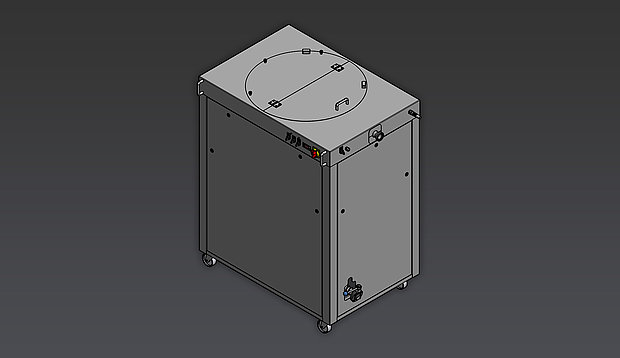

- PLC control, with 10" glass screen for comfortable operation and menu navigation.

- Standby function - temperature increase in the tank and interval control for the agitator to ensure a perfect decrystallization during the work pause

- Different chocolate temperatures and settings (recipes, products) are freely programmable

- Ready-to-plug-in preparation for retrofitting of vibrating tables and dosing system

- Intermediate pump electronically adjustable - conveying capacity up to 2000 kg/hr.

- Intermediate tank for pump heated, temperature adjustable

- Interior heating - temperature adjustable, with fan for even distribution of heat

- Smooth start-up of the agitator due to the use of a frequency converter - Thus lower load on the mechanical components and long service life

- Level measurement 'minimum - maximum' via indicator light - ready to plug in prepared for automatic charging via external dissolver with pump

- Pouring tube height adjustable, swiveling and removable for cleaning

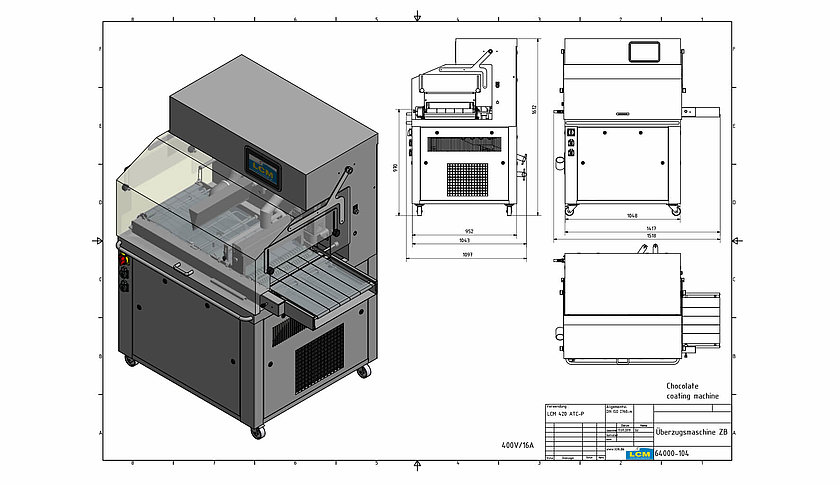

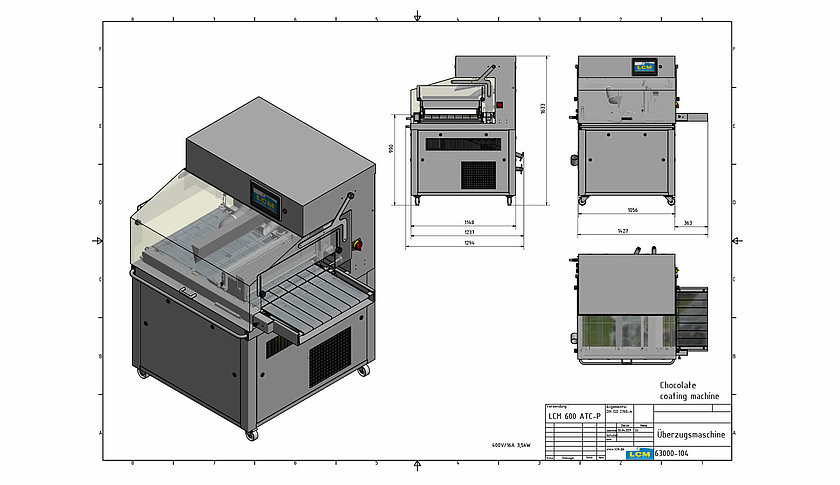

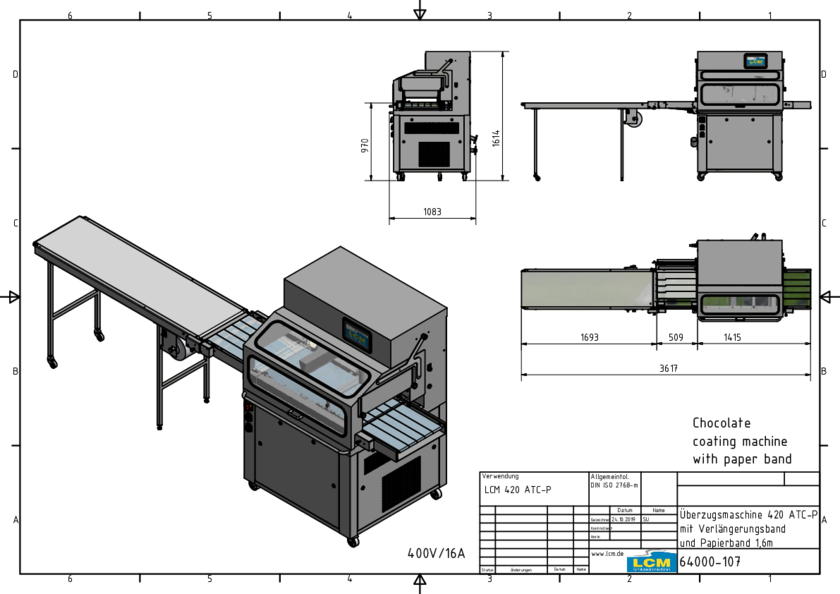

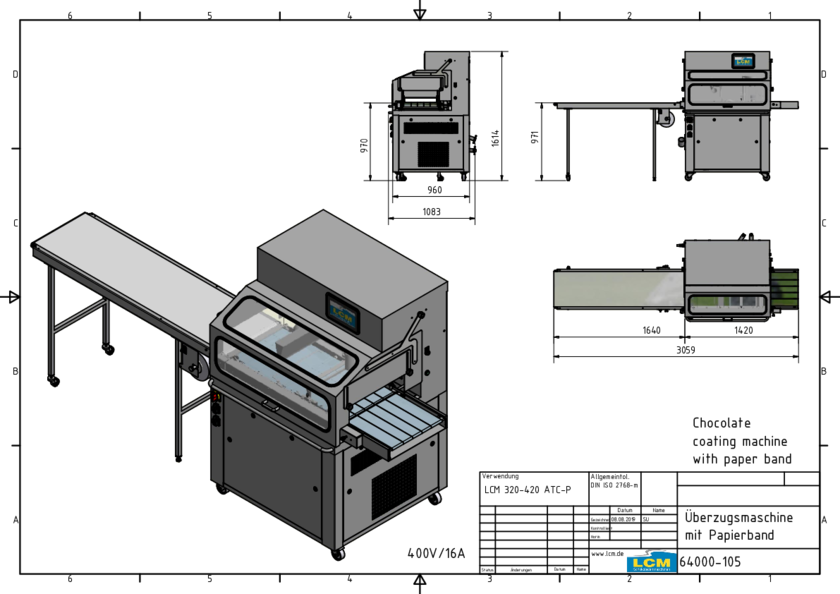

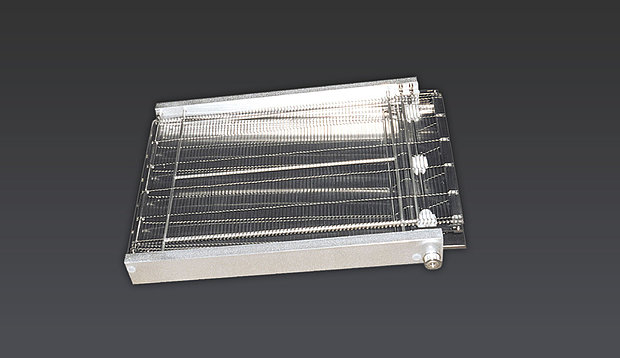

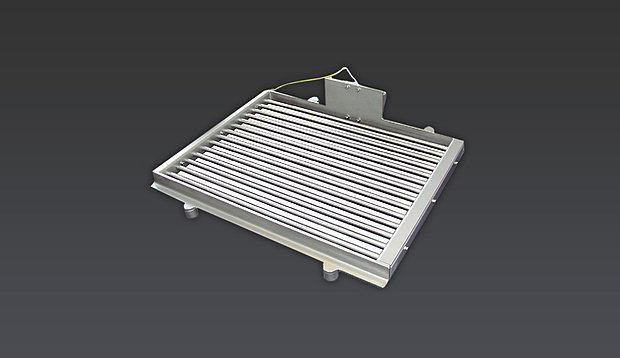

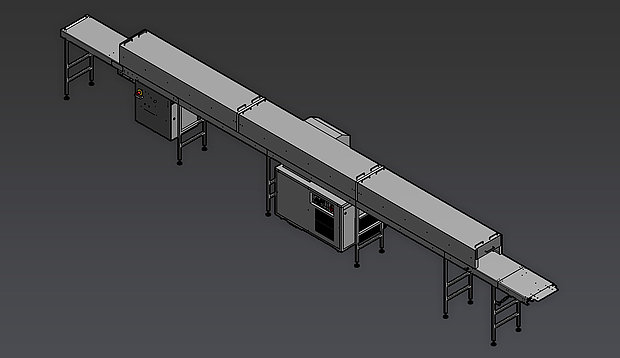

- Covering grid belt; easily removable and therefore very easy to clean, dishwasher safe Total length 1.4 meters

- Infeed grating belt separate from the overlay belt, feeding area 40 cm, very narrow transfer even for smallest products

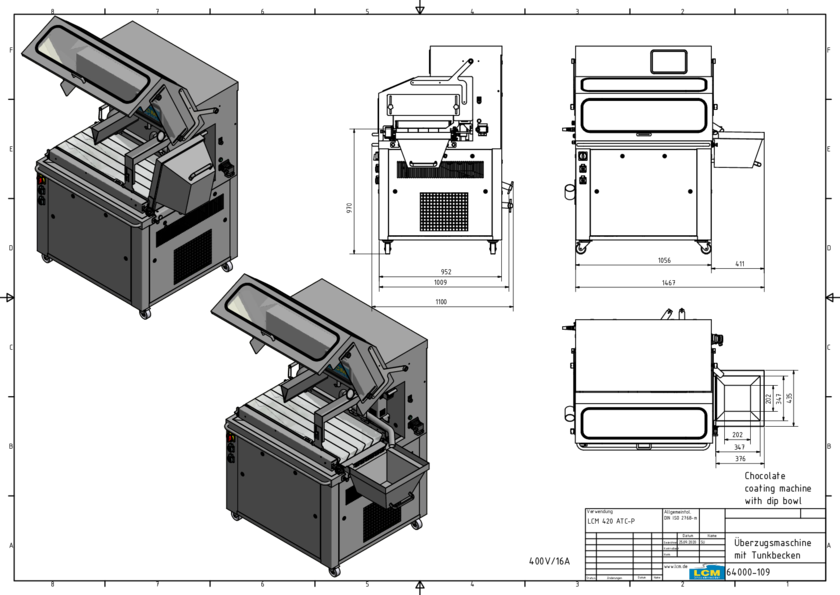

- Floor draining device included

- Veil box continuously adjustable in height up to 10 cm

- Continuously adjustable blower with filter for blowing off the chocolate after coating

- Blower shaft removable and adjustable in height up to 10 cm

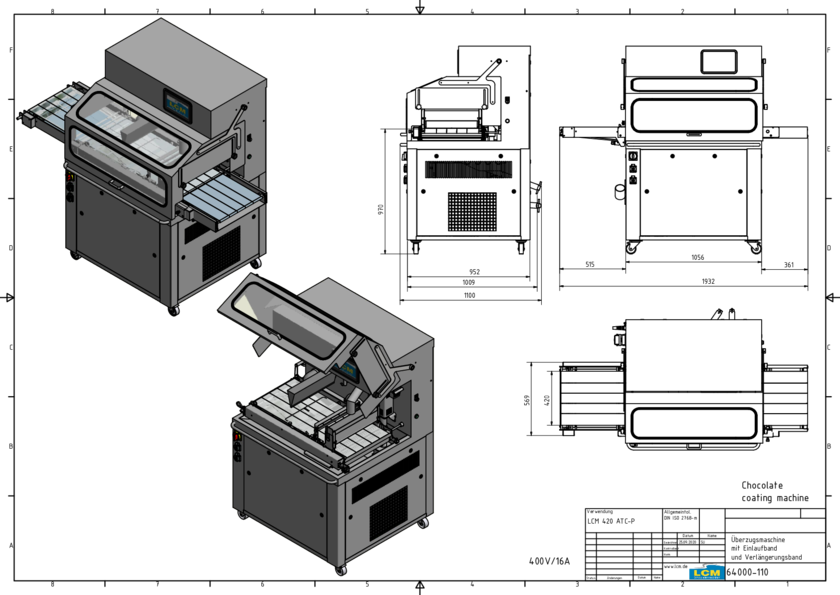

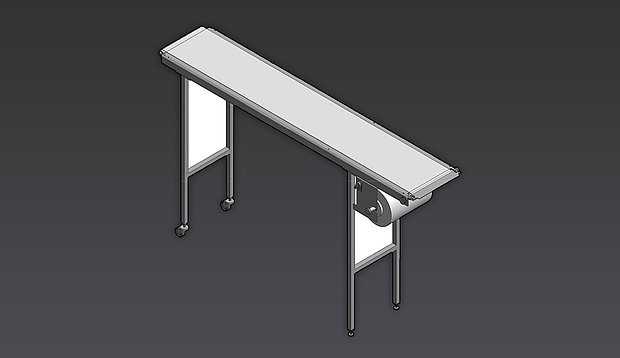

- Paper discharge belt with paper roll for hanging, total length 1.6 meters - ( except LCM 600 ATC-P )

- Start-stop system for one-man operation, and for extremely effective use of the paper

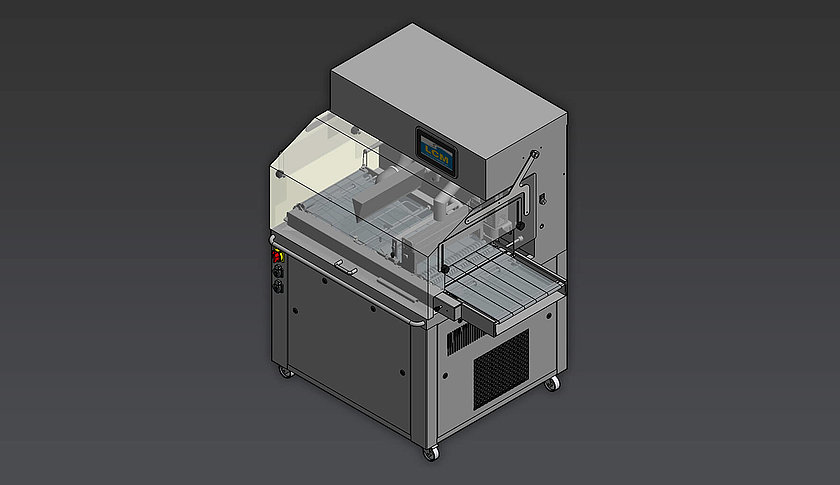

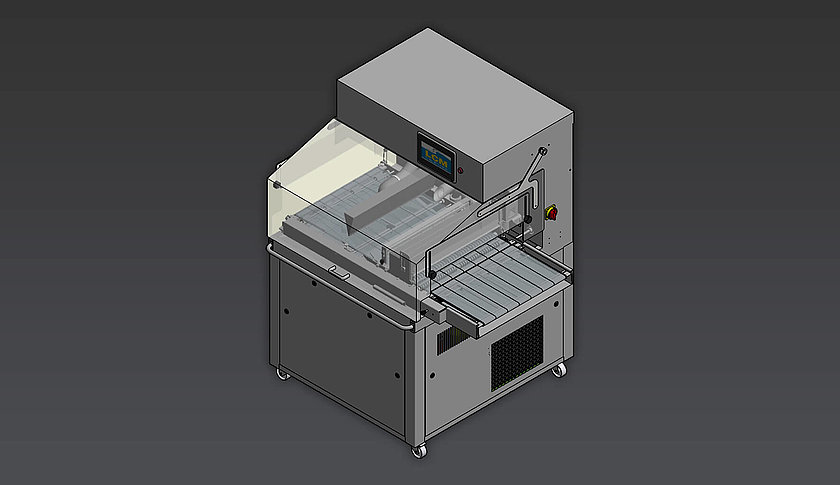

- Plastic hood 1-piece with hinge for opening by means of gas pressure damper

- residual current circuit breaker according to DIN VDE 0100-100 - safety of persons

- Machine housing completely made of stainless steel, mobile on swivel castors